NEWS

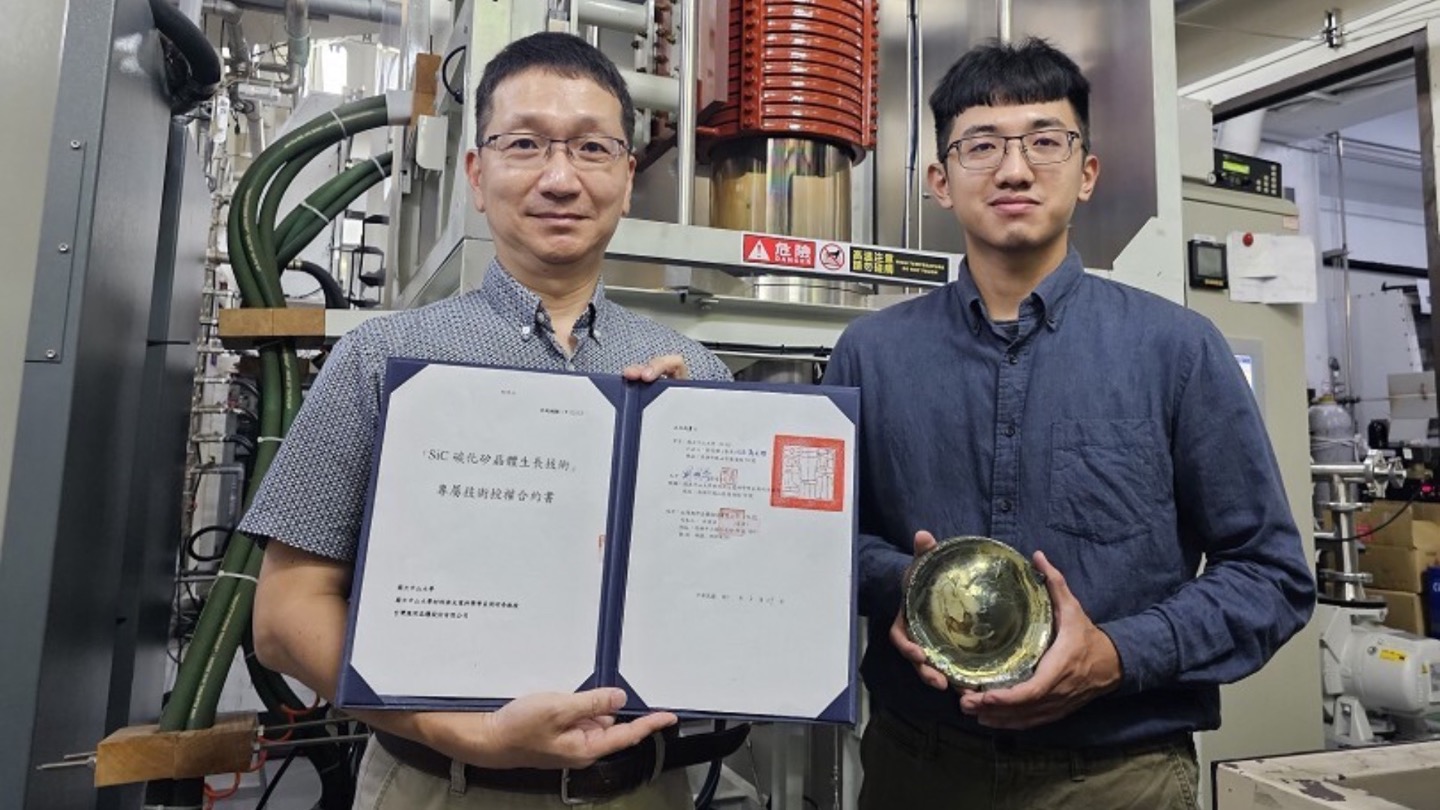

A 50 million technology transfer project of the 6-inch crystal growth awarded to NSYSU

As global chip shortage has remained for years, efficiency and quality stability of crystal growth present evident prominence for semiconductor manufacturers. As the only laboratory that produces silicon carbide (SiC) in Taiwan, the next-generation semiconductor material, the Center of Crystal Research at National Sun Yat-sen University (NSYSU) has successfully developed the technology of growing SiC bulk crystal in 6-inch diameter. Dr. Mitch Ming-Chi Chou, the Chair Professor of Department of Materials and Optoelectronic Science and the Director of the Center of Crystal Research at NSYSU, indicated that the team incorporated academia-industry collaboration resources, such as China Steel Corporation (CSC) and China Steel Chemical. This collaboration enhanced the competitive advantage of Taiwan’s semiconductor material industries, including graphite thermal insulation materials, crucible, and crystal growth facilities. Besides, NSYSU has signed the technology transfer contract with Taiwan Applied Crystal Inc. (TAC) and its related industry association. The technology transfer project is a 5-year collaboration that yields profits of NT$ 50 million. The project, launched in July 2023, is expectedly to create pioneering competitive advantages for the next generation semiconductor industries in Taiwan.

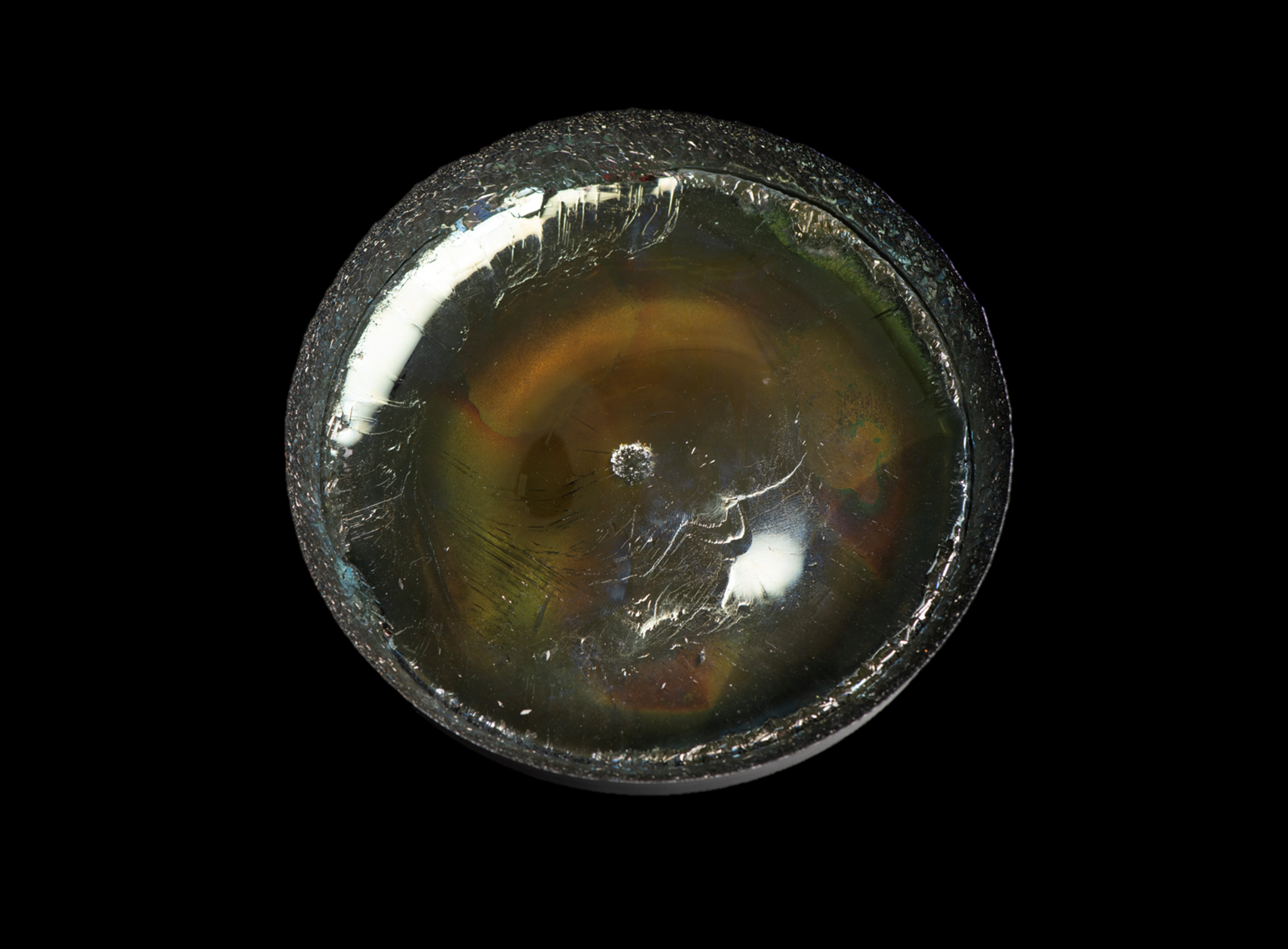

SiC bulk crystal grown at the Center of Crystal Research

SiC, the third- type (next-generation) semiconductor material, has been developed for decades. The recognized advantages of SiC include low loss, high power, low noise, and effective thermal dissipation. However, the technical threshold is also evidently high to implement the crystal growth procedures. Dr. Chou emphasized the prominence of SiC as the national strategic material that can be used in electric car manufacturing, photoelectric, satellite communication, military defense, and biomedical industries. Ahead of its peers in Taiwan, NSYSU has presented a remarkable breakthrough in crystal growth techniques through the successful development of n-type 4H 6-inch SiC single crystal and continuously enhanced the growth efficiency and quality stability of crystal growth.

During the research and development process, the NSYSU team innovated and collaborated with varied industrial partners in Taiwan. All the crystal growth hardware and software facilities, such as the power supply unit and control system, were manufactured in Taiwan. The crystal growth furnaces were manufactured by the start-up company supported by NSYSU’s Entrepreneurship and Innovation Center. The crucibles for SiC materials and the graphite thermal insulation materials were supported by the manufacturers in Kaohsiung. The crucibles manufacturers from Germany and Japan had invested effort in developing crucibles for decades. Dr. Chou also expressed gratitude for professional assistance from China Steel Corporation (CSC) and China Steel Chemical. In the process of enhancing crucibles’ thermal insulation property and the technical improvement when designing the thermal field, these two companies located in the same city as NSYSU had input much support.

Dr. Chou also specified the technology transfer project collaborating with Taiwan Applied Crystal Inc. (TAC) and its industrial association. From July 2023, NSYSU will implement its 6-inch SiC crystal manufacturing technology transfer to the company. The 5-year project yields profits of NT 50 million. During the contract period, exclusive authorization in the form of a buyout contract with NT 10 million per year will be implemented. To Taiwan Applied Crystal Inc. (TAC), this project represents the official kickoff in the next-generation semiconductor field. In the next five years, NSYSU and the company will work together in 6-inch and 8-inch large-sized n-type and semi-insulating Silicon Carbide (SI.-SiC) single crystals.

NSYSU has complied with its academia-industry collaboration principles in choosing partners. Dr. Chou indicated that the industrial association presents their technical advantages, patents, know-how, enthusiasm for research & development, and raising talents. It is also the upstream material provider of the industrial chain that operates a similar production methodology as the SiC crystal growth. “From July this year, the engineers from the company will attend the NSYSU weekly technical meetings to seamlessly transfer the technology from laboratory to plant, even during the period of new plant establishment in the future,” said Dr. Chou.

“In addition to optimizing the SiC growth technology, the NSYSU team is currently developing the Ga2O3 bulk crystal for the fourth-generation semiconductor,” said Dr. Chou. In the next stage, the center plans to cooperate with chemical engineering companies aiming to enhance the innovative techniques of rare earth elements purification and waste processing and fortify the competitive advantages for Taiwan semiconductor industries.

As the only laboratory that has the capacity to grow SiC crystal in Taiwan, the next-generation semiconductor material, the Center of Crystal Research at NSYSU has successfully developed the SiC bulk crystal in 6-inch diameter. Dr. Mitch Ming-Chi Chou, the Chair Professor of the Department of Materials and Optoelectronic Science and the Director of the Center of Crystal Research at NSYSU, indicated that NSYSU signed the technology transfer contract with Taiwan Applied Crystal and its related industrial association. The technology transfer project, launched in July 2023, is a 5-year collaboration that yields profits of NT$ 50 million.